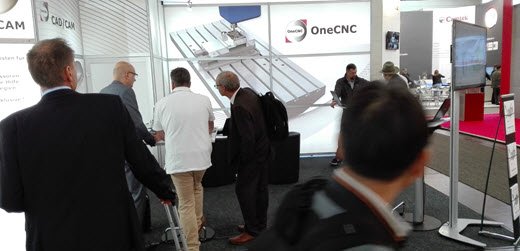

OneCNC Deutschland at EMO 2017 Hannover

OneCNC Deutschland at EMO 2017 held in Hannover September 18 to September 23

EMO is a fantastic window on the international engineering market. Here you can meet visitors from all over the world. For doing international business, there is simply no alternative to EMO.

There were 2,200 exhibitors and 130,000 visitors and sales deals of some 8 Billion Euros was the achievement of EMO 2017

EMO gives OneCNC a unique opportunity to show our customers how we can apply the OneCNC CAD-CAM solutions for their benefit which was clearly confirmed by the many demonstrations and conversations at our stand.

OneCNC application engineers talks were very promising indeed, both in terms of initial queries and firm orders. We have also gained many ideas for future development discussing our products with European customers.

OneCNC has a strong presence in Europe and our application engineers were kept busy demonstrating the advantages of the complete range of OneCNC CAD-CAM Solutions.

OneCNC Deutschland have extensive practical expertise in all facets of CAD CAM manufacture and provide in-house training, on-line training, or on-site training for all products.

OneCNC Deutschland offers on-site training in your shop manufacturing your parts.

If you were unable to attend for a personalized demonstration of the OneCNC CAD CAM Solutions we remind you that on-line demonstrations can be arranged at a convenient time so that you can evaluate first hand without leaving your shop.

For Further Information Contact >> OneCNC Deutschland

OneCNC Updates

OneCNC XR9 Release 74.80

Apr 01 2024

OneCNC XR9 Release 74.77

Feb 28 2024

OneCNC XR9 Release 74.68

Feb 13 2024